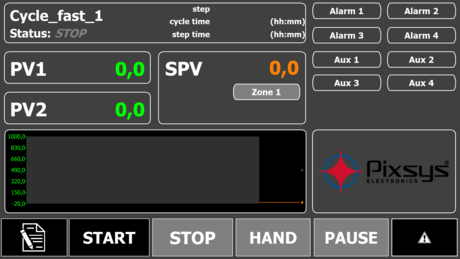

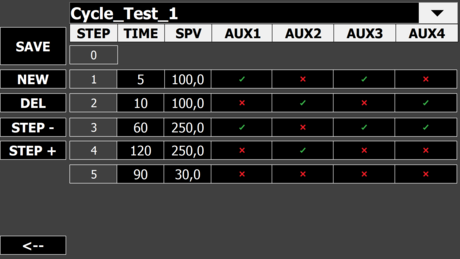

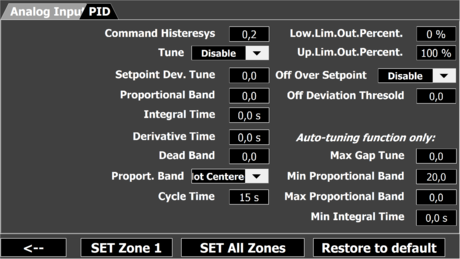

The KTD system is dedicated to the management of electric/gas kilns and industrial dryers, allowing PID control + adaptive Auto-tuning of up to 8 zones. Each zone can follow its own control loop according to the construction characteristics of the kiln.

The software is fully parameterizable and integrates the functions typically required for heat treatment plants, including automatic cycle recovery in case of power failure, end-of-step waiting in case of delays/inefficiencies, control of the process difference between zones, and delayed/programmed cycle start.

The KTD710 and KTD810 kits make available advanced features that meet the requirements of Industry 4.0 :

- VNC and HTML5 WebServer services for remote control, even from a PC outside the company network, via VPN created by PixsysPortal service;

- Energy consumption monitoring using the optional EnergyMeter 2100.35.032;

- Reports of executed cycles exportable in CSV format via USB key or via FTP.

- Furnace status sharing via ModbusTCP for easy integration with company MESs.

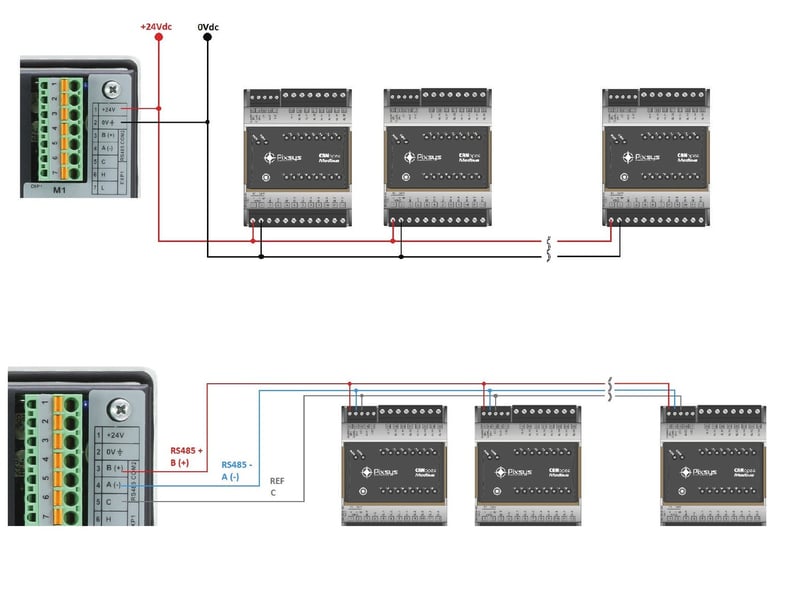

The kit consists of a 4'' (KTD410), 7'' (KTD710) or 12'' (KTD820) touchscreen operator panel and a variable number of DRR460 PID controllers, combined with one or two MCM260X-4AD digital I/O modules .

|

ORDERING CODES |

KTD410-EK2 |

KTD710-EK2 |

KTD710-Gk2 |

KTD820-EK2 |

KTD820-GK2 |

|---|---|---|---|---|---|

|

Power supply |

24 V DC | ||||

|

Consumption |

6 Watt/VA | ||||

|

Processor |

ARM Cortex A8 @ 1 GHz | ||||

|

Memory RAM |

512 MB DDR3 | ||||

|

Memory SSD/Flash |

eMMC 2 GB | ||||

|

Display |

4.3" TFT touch screen LCD, 480x272 pixel resolution - 16:9 format, 260k colours (16 bit), 280 cd/m2, lifetime typ.20000h @ 25°C, integrated 4-wire resistive touch |

7" TFT touch screen LCD, 800x480 pixel resolution - 16:9 format, 260k colours (16 bit), 280 cd/m2, lifetime typ. 20000h @ 25°C, integrated 4-wire resistive touch | 12.1" TFT touch screen LCD, 1280x800 pixel resolution - 16:9 format, 16.7M colours (24 bit), 400 cd/m2, lifetime typ. 50000h @ 25°C, integrated 4-wire resistive touch | ||

|

Clock | Real-Time Clock with Battery Back-up | ||||

|

Analogue inputs |

2 |

2..8 |

2..8 |

2..8 |

2..8 |

|

Digital inputs |

4 |

8..16 |

8..16 |

8..16 |

8..16 |

|

Digital outputs - SSR |

8 |

2..4 |

2..4 |

2..4 |

2..4 |

|

Relais outputs |

- |

8..16 |

8..16 |

8..16 |

8..16 |

|

Analogue outputs | 2 |

2..4 |

2..4 |

2..4 |

2..4 |

|

Serial communication |

CANopen for module MCM260X-9AD |

RS485 for I/O modules (MCM260X) and controllers (DRR460) | |||

|

Ethernet |

2x 10 / 100 Mbit/s - with separate MAC | ||||

|

USB |

1x USB 2.0 (only on the back) | ||||

|

Supervision protocol |

Modbus TCP | ||||

|

Regulation algorith |

Multi-zone PID with auto-tuning | ||||

|

Valve control algorithm |

Open/close valve control logic | ||||

|

Backup Functions |

Saving the running cycle with recovery function | ||||

|

Gas kiln control |

NO |

NO |

Sì |

NO |

Sì |

|

Cycles/programmes |

99 |

99 |

99 |

99 |

99 |

|

Steps/segments |

20 |

25 |

25 |

25 |

25 |

|

Remote control (VNC) and integrated VPN | Pixsys Portal software included for remote control and remote assistance | ||||

- KTD410-EK2KIT HMI 4" - MANAGEMENT OF ELECTRIC OVENS - 2 ZONES

- KTD710-EK2KIT HMI 7" - MANAGEMENT OF ELECTRIC OVENS - 2 ZONES

- KTD710-GK2KIT HMI 7" - MANAGEMENT OF GAS OVENS - 2 ZONES

- KTD820-EK2KIT HMI 12" - MANAGEMENT OF ELECTRIC OVENS - 2 ZONES

- KTD820-GK2KIT HMI 12" - MANAGEMENT OF GAS OVENS - 2 ZONES