ATR464 is a programmer dedicated to the automation of industrial ovens or laboratory ovens, dryers, heat treatment systems, and in general the management of a process involving cycles/profiles with control of the process variable in relation to time.

ATR464 allows the programming of 15 cycles/profiles, each one including up to 30 steps/segments, all free configurable by the user as ramp/soak/cooling.

The device integrates software functions typically required in oven/furnace management: Waiting (in the case the process is delayed in comparison to programmed setpoint) and Cycle Recovery mode (after any power failure). Special function for gas kilns management are available (code -15ABC).

Like other Pixsys programmers, ATR464 stands out for user-friendly interface and programming mode even for inexperienced operators.

Parameter configuration and cycle programming is possible via MyPixsys App on smartphone thanks to NFC/Rfid technology or on PC with MyPixsysLab software as well as directly from keyboard.

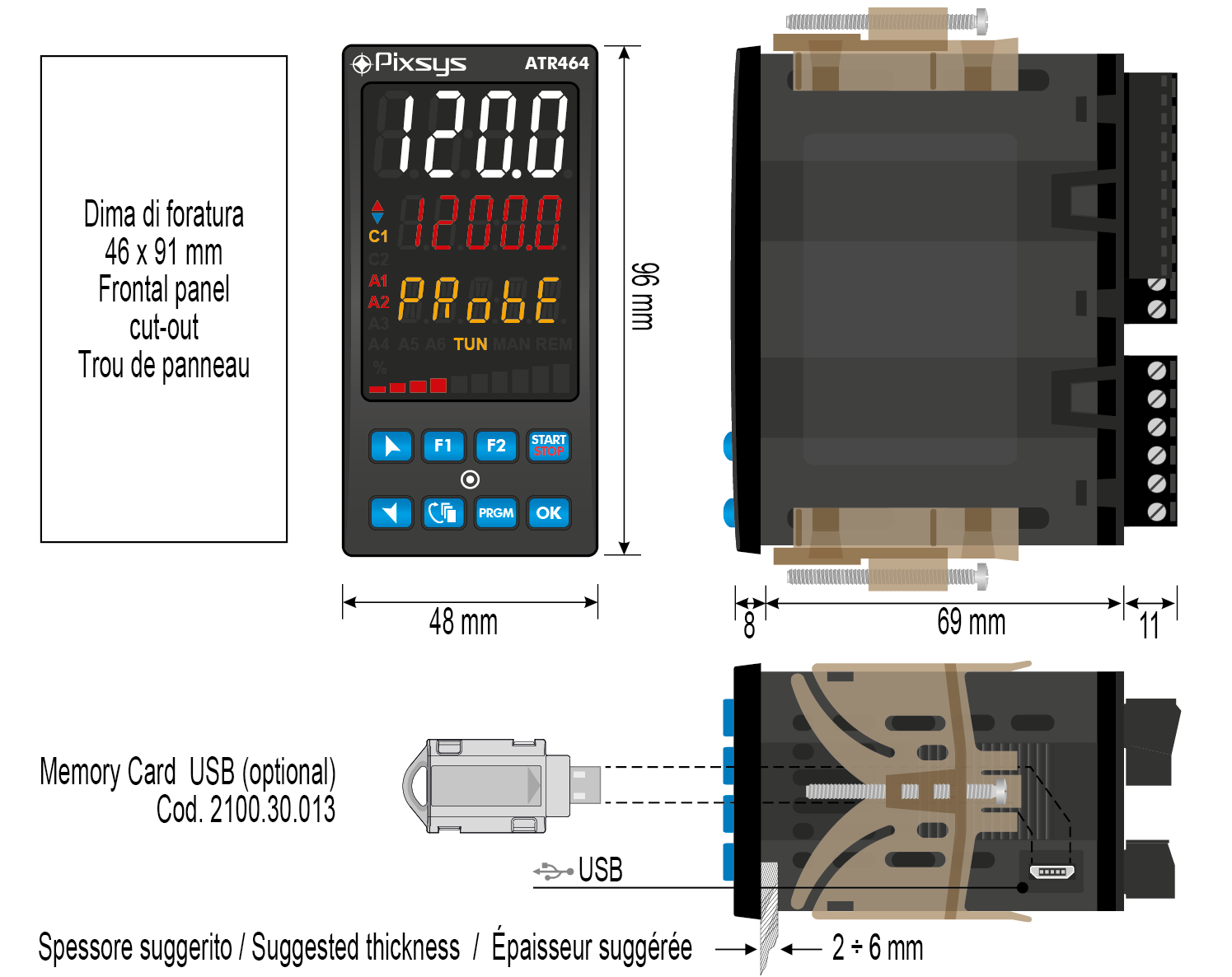

- Dimensions48 x 96 x 88 mm

- MaterialBox and front panel: PC UL94V2

- WeightApprox. 245 g

- SealingFront panel: IP65, Box and terminal blocks: IP20

- Operating conditionsTemperature 0-45 °C, humidity 35..95 RH%

- CertificationsCE, UL

| ORDERING CODES | ATR464-15ABC | ATR464-24ABC-T |

|---|---|---|

| Power supply | 24..220 V AC / DC ±10% 50/60 Hz - galvanic isolation 2,5KV | |

| Power consumption | 5,5 Watt/VA | 7 Watt/VA |

| Display | Display 4 digit 0,63" white + Display 5 digit 0,39" red + Display 5 digit 0,33" yellow+ bar graph + 12 signalising leds | Display 4 digit 0,63" white + Display 5 digit 0,39" red + Display 5 digit 0,33" yellow + bar graph + 12 signalising leds |

| Analogue inputs | 1x Ris. 16bit, programmable for thermocouples K, S, R, J, T, E, N, B (automatic compensation of cold junction -25..85°C, accuracy @25°C ±0,2% F.S. or ±1 digit), Thermoresistances PT100, PT500, PT1000, Ni100, PTC1K, NTC10K (B 3435K), Process signals 0/4..20mA (40000 points), 0...1/5/10V (54000 points), 0..60mV (16000 points), Potentiometers F.S. 1/150Kohm (50000 points). | 2x Ris. 16bit, programmable for thermocouples K, S, R, J, T, E, N, B (automatic compensation of cold junction -25..85°C, accuracy @25°C ±0,2% F.S. or ±1 digit), Thermoresistances PT100, PT500, PT1000, Ni100, PTC1K, NTC10K (B 3435K), Process signals 0/4..20mA (40000 points), 0..1/5/10V (54000 points), 0..60mV (16000 points), Potentiometers F.S. 1/150Kohm (50000 points). |

| Digital inputs | 4 xPNP | 4 XPNP |

| Digital outputs | 2 x PNP configurable 12VDC - 25mA max or 24VDC - 15mA max | 2 x PNP configurable 12VDC - 25mA max or 24VDC - 15mA max |

| Relais outputs | 5 x (5 A - 250 V AC resistive load) | 4 x (5 A - 250 V AC resistive load) |

| Analogue outputs | - | 2 x 4..20 mA (40000 points ± 0,2% F.S.) or 0..10 V DC (40000 points ± 0,2% F.S.) |

| Serial communication | - | RS485 (1200..115200 Baud) |

- Cycles / Profilesup to 15

- Stepsup to 30 for every cycle (the max duration per step is 99.59 hh.mm)

- Control algorithmsON - OFF with hysteresis, P., P.I., P.I.D., P.D. time proportional

- TuningManual or automatic

- Alarm modeAbsolute / Threshold, Band, High / Low deviation. Alarm with optional Manual reset. Loop Break Alarm

- Dual P.I.D.Heating / Cooling with dual P.I.D.

- Open / Close logicsOpen / Close logics for motorized valves

- Software parameter configurationsoftware MyPixsysLab, App MyPixsys

- Data protectionLock of Cycles - Access to parameters by Password