ATR621 is a single-loop PID Process controller, specifically designed for the automation of industrial ovens, climatic chambers, dryers and in general for the management of thermal processes, requiring the programming of cycles/profiles with control of the process variable in relation to time.

ATR621 allows the programming of 15 cycles/profiles with up to 45 steps/segments , all free programmable y the user as rising/dwell/cooling steps.

The cycle programming is simple and intuitive even for the inexperienced operator.

The instrument integrates software functions typically required in oven management: End-of-Step Wait (in case of process delay on the programmed setpoint) and Cycle Recovery mode (after any power failure).

All options are configurable from the keyboard.

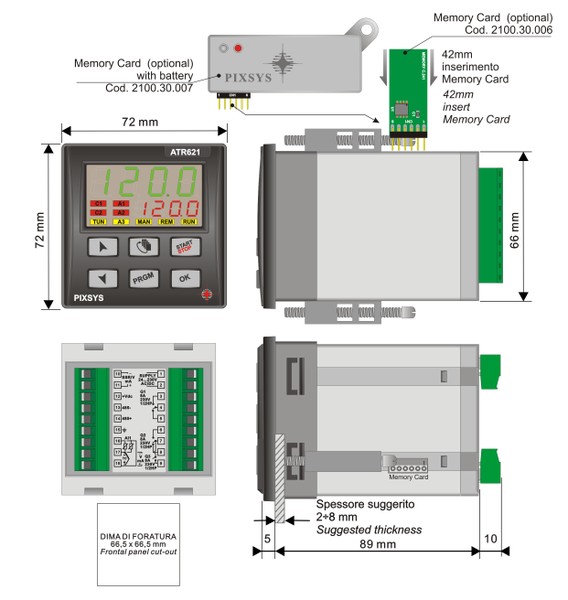

Programming is facilitated by MEMORY-CARDS that allow all parameters and cycles to be quickly duplicated.

- Dimensions72 x 72 x 99 mm

- MaterialBox: PC UL94V2 self-extinguishing, front panel: PC UL94V2

- WeightApprox. 250 g

- SealingFront panel: IP65, Box IP30 and terminal blocks: IP20

- Operating conditionsTemperature 0-45 °C, humidity 35..95 RH%

- CertificationsCE, UL

| ORDERING CODES | ATR621-12ABC | ATR621-13ABC-T | ATR621-14ABC |

|---|---|---|---|

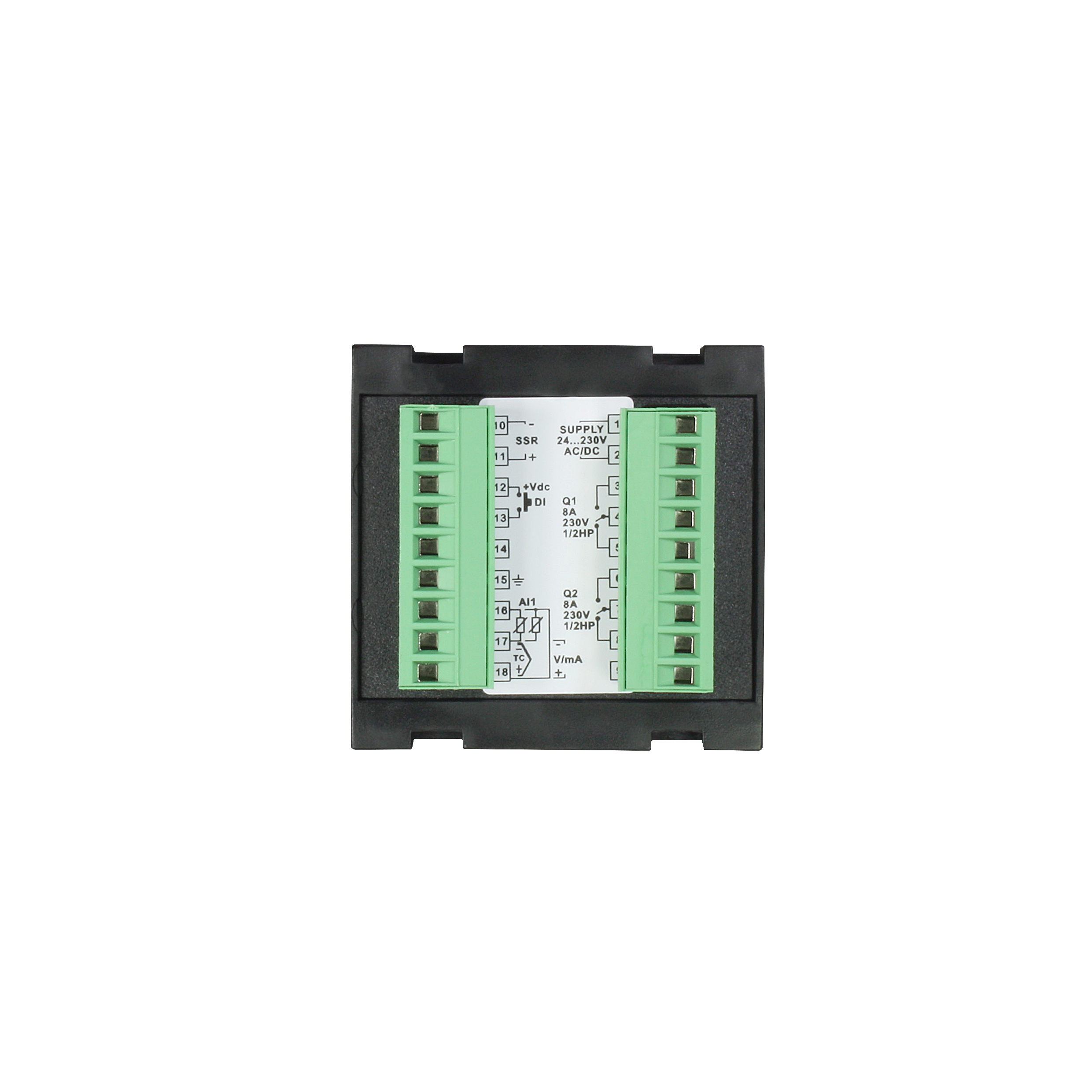

| Power supply | 24..230 V AC / DC ±15% 50/60 Hz - galvanic isolation 2,5KV | ||

| Power consumption | 5,5 Watt/VA Display verde 4 cifre 0,56 , rosso 4 cifre 0,3" e 6 signaling leds | ||

| Display | Display 4 digit 0,56" green + Display 4 digit 0,3" red + 6 signalising leds | ||

| Analogue inputs | 1x Ris. 16bit, programmable for thermocouples K, J, S, R (automatic compensation of cold junction 0..50°C, precision @25°C ±0,2% F.S. oppure ±1 digit), Thermoresistances PT100, PT500, PT1000, Ni100, PTC1K, NTC10K (B 3435K), Process signals 0/4..20mA (40000 points), 0..10V (54000 points), 0..40mV (16000 points), Potentiometers F.S. 6/150Kohm (50000 points). | ||

| Sampling time | Programmable up to 4,1 ms (frequency from 4,12Hz up to 242Hz) | ||

| Digital inputs | 1 xPNP | - | 1 xPNP |

| Digital outputs | 1 x PNP 12VDC - 30mA max | 1 x PNP 12VDC - 30mA max | - |

| Relais outputs | 2 x (8 A - 250 V AC resistive load) | 3 x (8 A - 250 V AC resistive load) | 3 x (8 A - 250 V AC resistive load) 1 x (5A - 30V AC resistive load) |

| Analogue outputs | - | 1 xDigitale PNP 12VDC - 30mA o 4..20 mA (40000 points ± 0,2% F.S.) o 0..10 V DC (40000 points ± 0,2% F.S.) | - |

| Serial communication | - | RS485 (1200..115200 Baud) galvanically isolated | - |

- Cycles / Recipesup to 15

- Stepsup to 45 for every cycle (the max duration per step is 99.59 hh.mm)

- Control algorithmsON - OFF with hysteresis, P., P.I., P.I.D., P.D. time proportional

- TuningManual or automatic

- Alarm modeAbsolute / Threshold, Band, High / Low deviation. Alarm with optional Manual reset. Loop Break Alarm

- Dual P.I.D.Heating / Cooling with dual P.I.D.

- Soft-StartRising gradient expressed as Degrees / Hour

- Open / Close logicsOpen / Close logics for motorized valves

- Software parameter configurationMemory Card, software LABSOFTVIEW, EASY-UP codes

- Data protectionLock of Command/Alarm Setpoints - Access to parameters by Password

- Communication protocolsRS485 Modbus RTU - Slave (13ABC-T model)

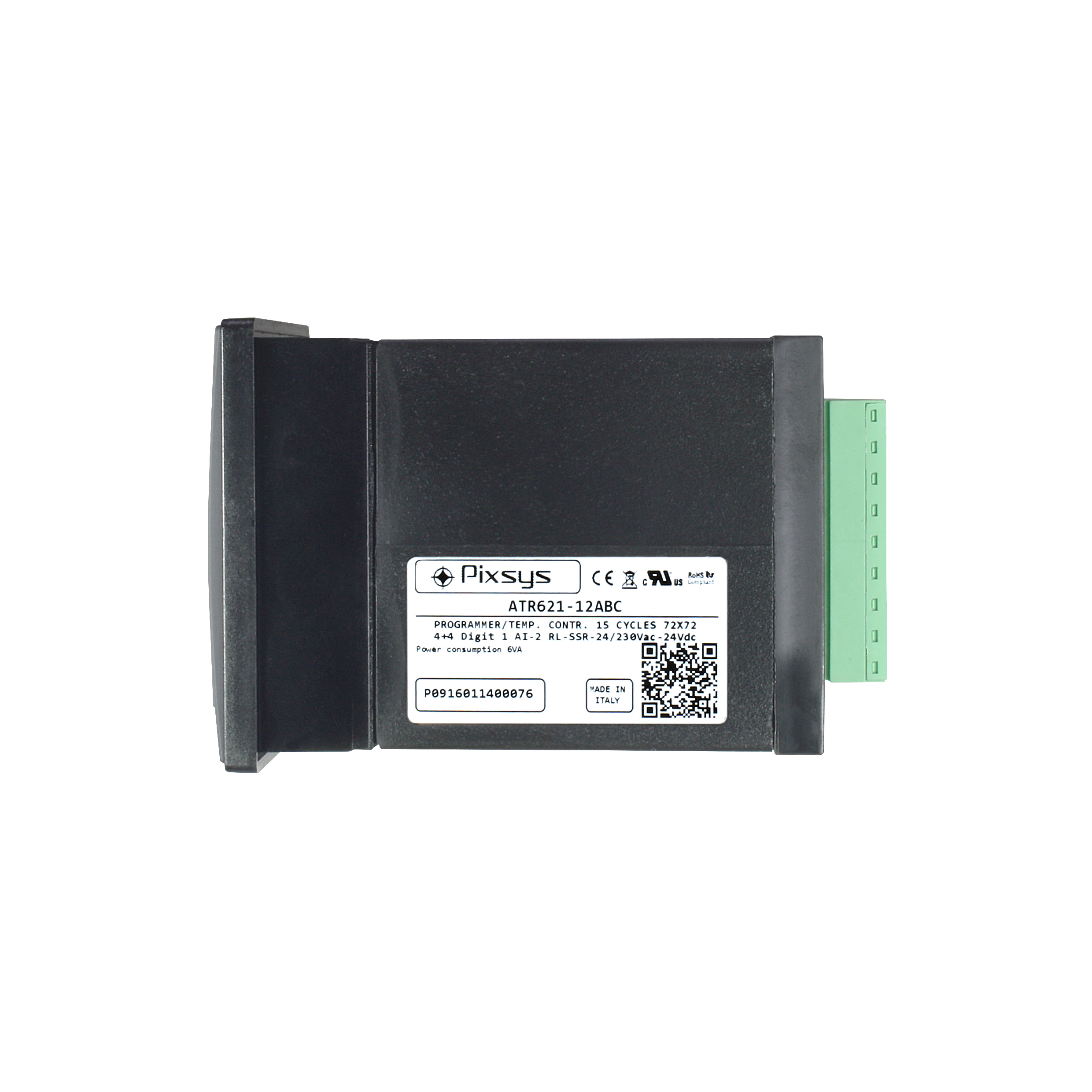

- ATR621-12ABCPROGRAMMER/TEMP. CONTR. 15 CYCLES 72X72 4+4 Digit 1 AI-2 RL-SSR-24/230V

- ATR621-13ABC-TPROGRAMMER/TEMP. CONTR. 15 CYCLES 72X72 4+4 Digit 1 AI-3 RL-SSR-V/mA-RS485

- ATR621-14ABCPROGRAMMER/TEMP. CONTR. 15 CYCLES 72X72 4+4 Digit 1 AI-4 RL-24/230V